100% Guaranteed

Premium Quality

10 Year Warranty

Professional Installation

We Supply and Install Premium

Mirrored, Colour & Printed Designs

for UK Kitchens.

We Supply and Install Premium

Mirrored, Colour & Printed Designs for UK Kitchens.

Expert UK Installation Team

Premium Quality Toughened Safety Glass

Affordable Price

Crafting Your Dream Kitchen with Custom Glass Splashback Finishes.

For 15 years, CreoGlass® has been the trusted name for supplying sophisticated, made-to-measure kitchen splashbacks—available in a full range of Mirrored, Colour, Printed, Glitter, and Premium finishes. All pieces are expertly engineered from resilient toughened safety glass, providing both a stunning feature and a hygienic solution, backed by our promise of stress-free project management.

Our Range of Kitchen Glass Splashbacks

Our Range of Kitchen Glass Splashbacks

Explore our vibrant collections and choose the perfect glass splashback to ignite your kitchen's style and functionality.

Mirrored Splashbacks

Our custom-cut, toughened glass splashbacks feature a highly reflective mirror finish. The durable, heat-resistant, easy-clean surface instantly creates the illusion of more space and depth, adding a luxurious, bright finish to any modern kitchen.

Available in: Toughened Mirror, Antique Toughened Mirror, Patterned Mirror, Striped Mirror, Non-toughened Mirror and Antique Non-toughened Mirror.

Colour Splashbacks

Get the perfect blend of style and substance. Our colour glass splashbacks deliver vibrant, high-gloss colour with a robust, heat-resistant, easy-maintenance finish. They instantly allow you to personalize your space and create a seamless, contemporary focal point, making a distinctive design

Available in: Plain Colour, Matt Finish and Metallic.

Printed Splashbacks

Design your own masterpiece! Our Printed Splashbacks seal your high-definition image permanently behind toughened, heat-resistant glass. Get a vibrant, easy-wipe finish that creates a stunning, custom focal point without sacrificing kitchen practicality.

Available in: Wave, Gradient, Food, Abstract, Stones, Landscape, Textured, Floral, Patterned, Liquid Ink etc.

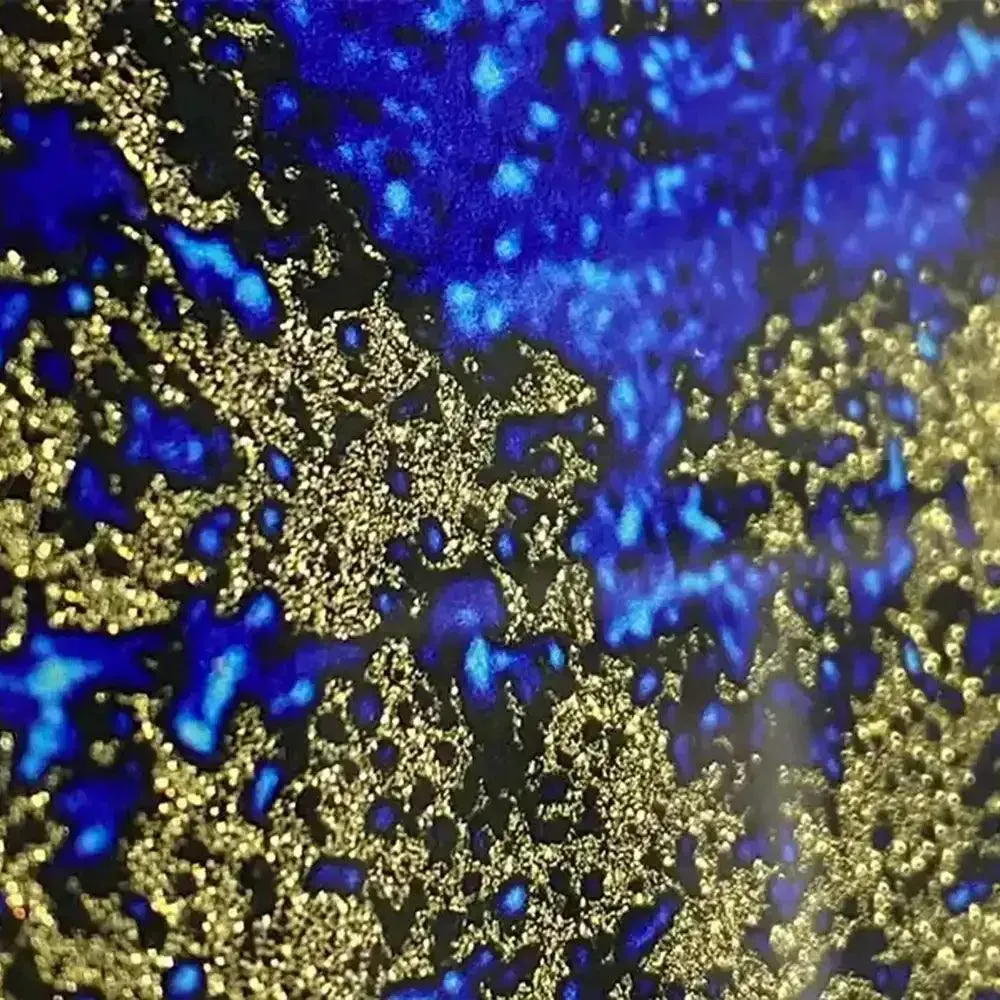

Glitter Splashbacks

Maximize light and glamour with our Glitter Splashbacks. Shimmering glitters are embedded behind toughened, heat-resistant glass, creating an enchanting, high-end focal point. The smooth, seamless surface ensures exceptional durability and easy cleaning.

Available in: 100% Luxury, 100% Fine Sparkle, Fibres Splashbacks etc.

Premium Splashbacks

Introducing Premium Splashbacks: the ultimate statement of quality and taste. Crafted from the finest toughened safety glass in an exquisite range of finishes, they offer superior heat resistance and durability. Achieve an effortlessly elegant, easy-to-clean focal point that elevates your entire kitchen ambiance.

Available in: Mica, Italian, Kiln, Gradient Extra, Crystal Stones and Liquid Ink Extra.

Mirrored Splashbacks

Our custom-cut, toughened glass splashbacks feature a highly reflective mirror finish. The durable, heat-resistant, easy-clean surface instantly creates the illusion of more space and depth, adding a luxurious, bright finish to any modern kitchen.

Available in: Toughened Mirror, Antique Toughened Mirror, Patterned Mirror, Striped Mirror, Non-toughened Mirror and Antique Non-toughened Mirror.

Colour Splashbacks

Get the perfect blend of style and substance. Our colour glass splashbacks deliver vibrant, high-gloss colour with a robust, heat-resistant, easy-maintenance finish. They instantly allow you to personalize your space and create a seamless, contemporary focal point, making a distinctive design statement in any modern kitchen or utility area.

Available in: Plain Colour, Matt Finish and Metallic.

Printed Splashbacks

Design your own masterpiece! Our Printed Splashbacks seal your high-definition image permanently behind toughened, heat-resistant glass. Get a vibrant, easy-wipe finish that creates a stunning, custom focal point without sacrificing kitchen practicality.

Available in: Wave, Gradient, Food, Abstract, Stones, Landscape, Textured, Floral, Patterned, Liquid Ink etc.

Glitter Splashbacks

Maximize light and glamour with our Glitter Splashbacks. Shimmering glitters are embedded behind toughened, heat-resistant glass, creating an enchanting, high-end focal point. The smooth, seamless surface ensures exceptional durability and easy cleaning.

Available in: 100% Luxury, 100% Fine Sparkle, Fibres Splashbacks etc.

Premium Splashbacks

Introducing Premium Splashbacks: the ultimate statement of quality and taste. Crafted from the finest toughened safety glass in an exquisite range of finishes, they offer superior heat resistance and durability. Achieve an effortlessly elegant, easy-to-clean focal point that elevates your entire kitchen ambiance.

Available in: Mica, Italian, Kiln, Gradient Extra, Crystal Stones and Liquid Ink Extra.

Single Sliding Glass Doors

- PMF

This is a Paragraph Font

Single Sliding Glass Doors

- Frameless

This is a Paragraph Font

Add a Title Here

This is a Paragraph Font

Add a Title Here

This is a Paragraph Font

Why Choose Creoglass® Glass Splashbacks?

Ultra-Clear Reflection

High-quality glass provides flawless clarity, helping you perfect form and track progress with accurate and crisp reflection.

Safe & Durable

Made from toughened safety glass that’s highly resistant to impact. If breakage ever occurs, it crumbles into small, blunt pieces instead of large sharp shards.

Custom Fit for Any Space

Made-to-measure mirrors for a seamless fit, whether for a compact home office or a large studio.

DIY-Friendly or Professional Install

With options between self-installation kits or expert fitting along with reliable delivery and after-sales support.,

Classic Splashbacks

Our Colour Splashbacks range offers versatile aesthetic control: Plain Colour Splashbacks deliver a seamless, high-gloss surface optimized for vibrant visual impact and simple cleaning; Matt Finish Splashbacks achieve a look of quiet luxury with a non-reflective, satin surface engineered to reduce glare and minimize fingerprints; and Metallic Splashbacks infuse industrial chic and dynamic depth, featuring fine metallic flakes embedded in the back coating, optimized to catch light and provide a high-impact shimmer.

Plain Colour

Splashbacks

Matt Finish

Splashbacks

Metallic

Splashbacks

Mirrored Splashbacks

Our reflective collection offers diverse visual effects and safety levels: Toughened Mirror Splashbacks provide a modern, expansive reflective surface that is heat-resistant and safe for use behind hobs; Antique Mirror Splashbacks feature a uniquely distressed, vintage finish ideal for character and warmth; Striped and Patterned Mirror Splashbacks introduce texture and sophisticated etched designs to create an artistic focal point; while Non-Toughened Mirrors offer cost-effective reflective glamour for accent walls and areas away from direct heat.

Toughened Mirror

Splashbacks

Antique Mirror

Splashbacks

Striped Mirror

Splashbacks

Patterned Mirror

Splashbacks

Antique Non-toughened Mirror Splashbacks

Non-toughened Mirror

Splashbacks

Printed Splashbacks

Our printed collection provides limitless aesthetic personalization: Abstract and Textured prints introduce contemporary visual depth and tactile illusion; Gradient prints offer seamless colour transitions for modern subtlety; Wave and Liquid Ink designs capture fluid motion and organic drama; while themed categories like Food, Cityscape, Floral, Stones, and Landscape allow for tailored imagery, transforming your splashback into a high-resolution, personalized masterpiece.

Wave

Splashbacks

Abstract

Splashbacks

Gradient

Splashbacks

Food

Splashbacks

Landscape

Splashbacks

Floral

Splashbacks

Stones

Splashbacks

Textured

Splashbacks

Liquid Ink

Splasbhacks

Glitter Splashbacks

Our Glitter collection delivers instant glamour and brilliance: We offer finishes ranging from 100% Fine Sparkles for a subtle, even shimmer to the highly concentrated 100% Luxury finish, both incorporating fine metallic fibres embedded in the glass backing; this range is optimized to catch and reflect light dynamically, transforming any kitchen wall into a captivating, durable, and dazzling focal point.

100% Luxury

Splashbacks

100% Fine Sparkle

Splashbacks

Fibres

Splashbacks

Premium Splashbacks

Our Premium collection represents the pinnacle of glass artistry and texture: Italian and Kiln finishes utilize specialized heating techniques to achieve unique structural depth and rich texture; Mica splashbacks incorporate mineral flakes for subtle natural shimmer and elegance; and our enhanced artistic options, Liquid Ink Extra and Gradient Extra, deliver unparalleled colour depth and dynamic fluidity; finally, Crystal Stones integrate fine crystallized elements for a truly luxurious, high-end tactile finish.

Mica

Splashbacks

Italian

Splashbacks

Kiln

Splashbacks

Gradient Extra

Splashbacks

Crystal Stones

Splashbacks

Liquid Ink Extra

Splashbacks

Glass Splashbacks: Effortless Elegance, Superior Shield

Give your kitchen the ultimate upgrade with custom glass splashback systems from CreoGlass. More than just wall covers, our precision-engineered splashbacks are carefully crafted for the demanding standards of modern cooking and minimalist design. We deliver a flawless, light-reflecting finish—the essential design tool for protecting walls, enhancing space, and defining the character of your cooking area.

Instantly transform your workspace into a sleek, hygienic, and elegant zone designed to help you cook in style and comfort.

Key Factors to Consider When Choosing Kitchen Glass Splashbacks

When selecting a glass splashback for your kitchen, balancing aesthetic desires with practical requirements is essential. Here are the most important factors to consider:

1. Safety and Durability (Toughened Glass)

Heat Resistance: If the splashback is located behind any hob (especially gas), it must be made from toughened (tempered) safety glass. Untoughened glass can shatter when exposed to extreme heat or sudden temperature changes.

Impact Resistance: Toughened glass is significantly stronger and more resistant to impact (e.g., knocking a pot against it) than standard glass.

Edge Finish: Ensure the edges are polished smooth to prevent injury and provide a professional, clean installation finish.

2. Aesthetics and Finish

Colour Accuracy (Low-Iron Glass): If you choose a plain or light colour, confirm the supplier uses low-iron glass. Standard glass has a slight green tint that can distort delicate colours like whites, blues, and pale greys.

Visual Effect (Finish Type):

High-Gloss/Plain Colour: Maximizes vibrancy and light reflection.

Matt Finish: Reduces glare and fingerprints, offering a sophisticated, soft look.

Mirrored: Creates the illusion of space and depth (consider toughened antique or standard mirror).

Printed/Patterned: Allows for personalization (photos, custom art, textures).

Glitter: Infuses the surface with fine metallic flakes or fibers, optimized to catch light and provide a dynamic, shimmering focal point.

Premium (Mica/Kiln/Textured): Offers the highest level of artistry, utilizing specialized processes like kiln-forming or mica infusions to create rich texture, unique structural depth, and unparalleled luxury.

Grout-Free Design: A major benefit is the lack of grout, which means easy cleaning and a seamless, uninterrupted look.

3. Kitchen Dimensions and Cut-Outs

Accurate Measurements/Templating: The glass must be manufactured to precise specifications, as it cannot be cut or drilled once it has been toughened. For complex areas, use a professional templating service to guarantee a perfect fit.

Electrical Fixtures: Count and precisely locate all electrical sockets, switches, light fittings, and cooker hood vents. These will require custom cut-outs in the glass panel.

Panel Size: Consider the maximum single-panel length achievable to minimize joins, especially on large, continuous walls.

4. Installation Method

Professional vs. DIY: Decide whether the complexity of the installation (custom cuts, large panels) warrants professional fitting or if a small, simple piece can be managed as a DIY project.

Wall Condition: The wall surface needs to be relatively flat and sound for proper adhesion, which is typically done using specialist silicone or adhesive.

5. Budget and Value

Cost Drivers: Custom sizes, low-iron glass, special finishes (like Metallic, Glitter, or Premium Kiln effects), and professional templating/installation will increase the overall cost.

Long-Term Value: While initial cost may be higher than tiles, glass offers superior durability, easier maintenance, and a contemporary look that provides strong long-term value.

Precision. Trust. Expertise

We are 15 years trusted company

Trusted for Over 15 Years

Our team of specialists is dedicated to ensuring every bespoke Creoglass product is crafted to the highest quality, exceeding your design expectations. As a company trusted for over 15 years, we guarantee reliable results and flawless installation.

A Decade of Reliable, On-Time Service

We don't just sell a dream, we deliver peace of mind. Our skilled experts ensure high-quality results from design to installation, backed by 15 years of industry trust.

Real Kitchens,

Real Results

How to Order Your Custom Glass Splashbacks

When selecting a glass splashback for your kitchen, balancing aesthetic desires with practical requirements is essential. Here are the most important factors to consider:

Request a Quote

Fill in your details and requirements.

Confirm Details

We’ll contact you to confirm sizes, options, and fitting needs.

Production

Bespoke measure & fit: usually 15–20 working days.

Delivery & Installation

We arrange delivery and offer a full professional installation for a safe, flawless finish.

Rough Measurements

Take initial width and height measurements of the area. Note where the splashback will start and end

Identify Fixtures

Mark the location and count of all electrical sockets, light switches, and vents that will require cut-outs.

Choose the Finish

Decide on the glass type (Colour, Mirrored, Printed, Glitter, Premium) and your preferred colour/design.

Quotation

Send your initial sketch, rough measurements, cut-out count, and chosen finish type to the supplier

Manufacturing

Once you accept the final quote, full payment or a deposit is required, and the glass is sent into production.

Installation

An installation date is booked once the finished glass is ready.

How to Order Your Custom Glass Splashbacks

When selecting a glass splashback for your kitchen, balancing aesthetic desires with practical requirements is essential. Here are the most important factors to consider:

Request a Quote

Fill in your details and requirements.

Confirm Details

We’ll contact you to confirm sizes, options, and fitting needs.

Production

Bespoke measure & fit: usually 15–20 working days.

Delivery & Installation

We arrange delivery and offer a full professional installation for a safe, flawless finish.

Rough Measurements

Take initial width and height measurements of the area. Note where the splashback will start and end

Identify Fixtures

Mark the location and count of all electrical sockets, light switches, and vents that will require cut-outs.

Choose the Finish

Decide on the glass type (Colour, Mirrored, Printed, Glitter, Premium) and your preferred colour/design.

Quotation

Send your initial sketch, rough measurements, cut-out count, and chosen finish type to the supplier

Manufacturing

Once you accept the final quote, full payment or a deposit is required, and the glass is sent into production.

Installation

An installation date is booked once the finished glass is ready.

STILL NOT SURE?

Common Questions About Our

Glass Splashbacks

Find quick answers on gym mirror materials, safety standards, installation requirements, and custom dimensions to start your home or studio project with confidence.

Are splashbacks safe for use behind all types of hobs, including gas?

Absolutely. All CreoGlass splashbacks are made from toughened (tempered) safety glass which is heat and impact resistant up to 400°C degrees, making them perfectly safe to use behind gas, electric, or induction hobs.

What type of glass does CreoGlass use to ensure accurate colour?

We typically use low-iron glass for our splashbacks. This glass has a reduced green tint compared to standard glass, ensuring that the colour you select—whether it's a bold hue or a subtle shade—is displayed with maximum accuracy and vibrancy.

Can CreoGlass match my splashback to a specific paint colour I've already chosen?

Yes, we offer a colour-matching service. We can match your splashback to virtually any paint colour from popular UK brands like Farrow & Ball, Dulux, and Crown. Simply provide us with the exact paint name or code.

What finishes and special effects are available in the CreoGlass range?

CreoGlass offers a wide variety of finishes beyond plain colour, including Mirrored, Printed (custom designs), Glitter, and LED Backlit options, allowing you to choose the perfect aesthetic for your kitchen.

What happens if I have electrical sockets or switches in the area I want covered?

We create precise cut-outs in the glass to perfectly accommodate sockets, switches, and other wall-mounted fixtures. These must be planned and fabricated during the manufacturing process, as toughened glass cannot be cut afterwards.

How thick are your standard kitchen glass splashbacks?

Our standard kitchen glass splashbacks are typically 6mm thick, which provides an ideal balance of durability, heat resistance, and a sleek, modern profile.

How do I clean and maintain my glass splashback?

Cleaning is simple and hygienic. The seamless, non-porous surface should be wiped down with a soft cloth and a non-abrasive household glass cleaner. Avoid using scouring pads or harsh, acidic chemicals.

Will the custom colour or printed image fade over time?

No. The high-quality paints and durable application techniques we use are applied to the back surface of the glass, protecting the finish from normal kitchen temperatures and indirect sunlight, ensuring the colour remains stable.

How do I get an accurate price estimate from CreoGlass?

To get an accurate guide price, you should email our sales team a basic sketch of your area, including the width, height, number of socket cut-outs, and a few pictures or drawings of your kitchen.

Do you offer a templating and installation service, or can I install it myself?

CreoGlass offers both a full professional templating and installation service (highly recommended for custom fits) and a DIY range for smaller, more straightforward projects, allowing you to choose the option that fits your budget and skills.

CONTACT US

Showroom address: Unit 29 Orbital 25 Dwight Road Watford, WD18 9DA.

Tel: +441923947454

Email: [email protected]

COMPANY

CUSTOMER CARE

LEGAL

© 2025 CreoGlass®, All rights reserved.